Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Select Language

PRODUCTS

Product Description

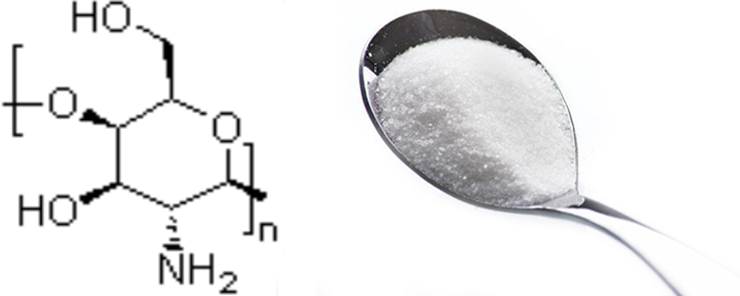

Sodium Alginate Powder

1.Introduction of Sodium Alginate:

Sodium alginate, a natural polysaccharide, has the stability, solubility, viscosity and safety required for excipients of pharmaceutical preparations. In 1881, the British chemist E.C. Stanford first conducted scientific research on the alginate extract from brown seaweed. He found that the alginate extract had several interesting properties, which had the ability to concentrate solution, form gel and film. Based on this, he put forward several applications for industrial production. However, alginate was not industrialized on a large scale until 50 years later.

2.Application of sodium Alginate:

1. Used for ice cream and cold spots to improve shape retention and fine tissue

2, pasty filling, meat sauce, gravy, frozen food, chocolate, butter flavored hard candy, cold point gel, gel soft sweets, syrup, emulsion.

3. It is used as a curing and removing agent of copper in beer production. It is removed after coagulation with protein and tannin

4. It can be made into film for anti stick packaging of candy

5. Printing and dyeing industry: mordant, finishing slurry and printing slurry. Textile industry: warp sizing, waterproof processing, lace manufacturing, water-soluble fiber

6. Cosmetics: toothpaste base material, shampoo, hair conditioner, etc

3.Application of Sodium Alginate in Food:

* Noodle food:

Adding 0.2% - 0.5% sodium alginate to the production of dried noodles, fish noodles, fast food noodles and cheese noodles can significantly increase the viscosity, prevent brittleness, effectively reduce the head breakage rate, be resistant to cooking, foam, non stick strips, strong gluten, high toughness, delicate, lubricating and chewy. When producing pasta and pastries such as bread, adding 0.1% - 1% sodium alginate can significantly prevent aging and drying, reduce chip falling, have muscle strength and good taste.

* Ice cream, popsicle and ice cream:

In the production of ice cream, popsicle and ice cream, 0.1% - 0.5% sodium alginate is generally added as a stabilizer to form a uniform mixture, which is easy to adjust the fluidity of the mixture when it is frozen and easy to mix. The product has good shape retention, smoothness, delicacy and good taste. It does not form ice crystals during storage, but also can stabilize the air bubbles. The expansion rate of the product is increased by about 18%. Increase the output by 15% - 17%, and make the products soft and elastic.

*Milk products and beverages:

Sodium alginate can be used as a stabilizer for frozen milk, frozen fruit juice and other drinks. Adding an appropriate amount of sodium alginate to frozen milk can significantly increase the taste, no viscosity and stiffness. In particular, adding 0.25% - 2% sodium alginate to yogurt can maintain and improve its curd shape, prevent the decline of viscosity in the process of high-temperature disinfection, and prolong the storage period to keep its special flavor unchanged. It can also be used as margarine thickener and emulsifier. In addition, it is added to the beverage to make a refreshing fruit syrup with saccharin and accessories, which has a smooth and uniform taste and is stable and non layered.

4. It is widely used in the production of candy, frozen sweets, food cores and fillings.

Using sodium alginate as the main additive, we can produce top-grade soft candy, such as fresh jelly, grape beads, lotus seed soup, tremella soup, red bean soup, etc. It can also be prepared in a certain proportion with other auxiliary materials. After freezing, a smooth and solid pudding can be obtained. In addition, the additives of sodium alginate and starch can be used to make candy that can replace the commonly known "glutinous rice paper". The lining packaging film of pastry can be used to prevent the closing of candy and the oil separation of pastry, and the effect is excellent. It can not only improve the strength and flexibility of the film, which is conducive to mechanized production, but also save grain and reduce cost. Adding sodium alginate to the core and filling of food obviously shows good gel performance and strong adhesion. For example, pie, moon cake, sandwich cake, broken fruit sweets and steamed stuffed buns have uniform texture and good taste.

*Health food:

Sodium alginate is an indispensable dietary fiber for human body. It has unique nutrition. It can combine organic matter, reduce cholesterol in serum and liver, inhibit the rise of total fat and total fatty acid concentration, improve the digestion and absorption of nutrients, and inhibit the absorption of radioactive strontium, cadmium and other harmful elements in the body. Because sodium alginate is a sodium carboxylate salt (containing - COONa), which can be dissolved in water, and anion loaded carboxylate ions (COO -) can combine with harmful heavy metal elements such as lead and mercury in human body to form heavy metal salt precipitation of alginate. It is insoluble in water, so it can be excreted with feces. Generally, sodium alginate is dissolved in water as an auxiliary material, mixed evenly, and then solidified into particle, strip and fiber paper shape, which can be made into solid beverage or meat like food.

4.Application:

Printing and dyeing, textile industry, cosmetics, solid drinks, dairy products, pasta cakes, candy sweets, functional foods, etc., but excluding infant products.

YOU MIGHT ALSO LIKE

GET IN TOUCH

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand. we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.